Conveyor Belt Lacing and Repair Kits

Conveyor Belt Lacing Options

Conveyor belts often need to be cut and spliced together to form an endless loop. This allows belts to be installed around pulleys and conveyor systems to move product. The two

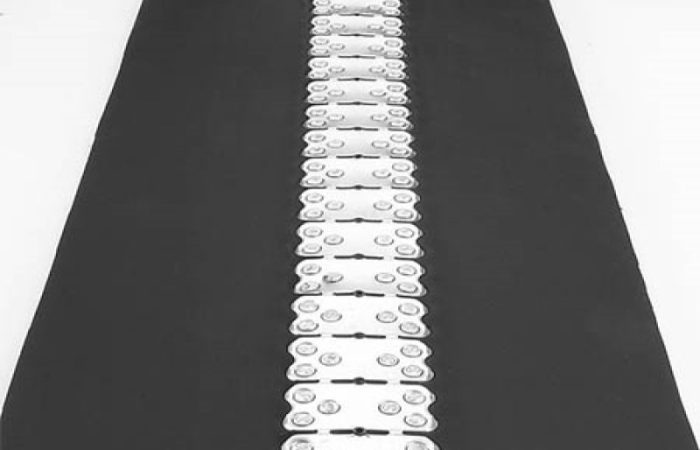

Alligator Staple Lacing

Lacing Repair Kits

Mechanical Lacing Types

Mechanical Belt Fasteners use staples, solid plates or hinged plates installed onto belts. Belt ends are joined endless using removable pins or permanent plate connections. Read more about Conveyor Belt Fasteners.

Bolt Solid Plate

Strong holding from top and bottom plate compression

Bolt Hinged Lacing

Strong, reliable, adjustable fastening over smaller pulleys

Rivet Solid Plate

High tension applications for a long lasting hold

Rivet Hinge Lacing

Popular on rubber plied and PVC solid woven belting

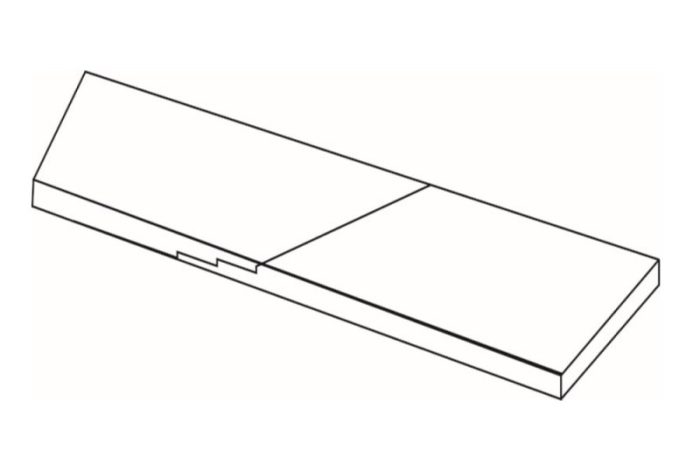

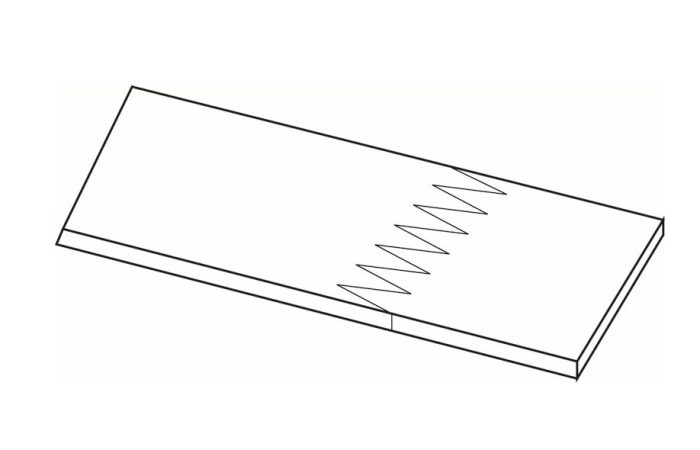

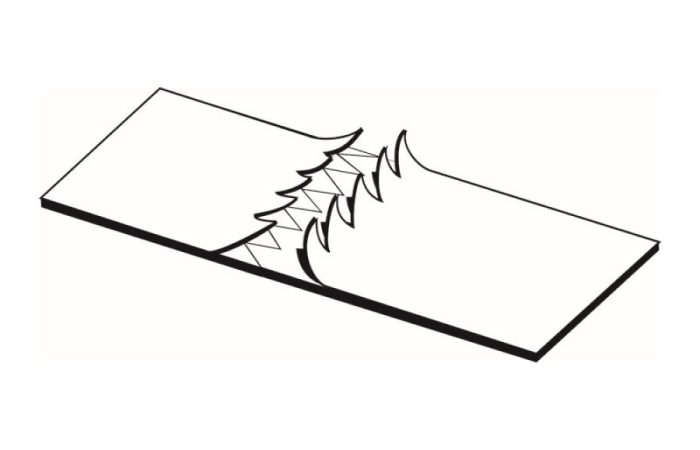

Vulcanized End Lacing Options

Vulcanized Endless Spliced Belts use chemicals or heat vulcanization to join belt ends. This often gives a stronger, permanent splice with no mechanical fasteners. Read more about Vulcanized Belt Lacing options.

Endless Lap Splice

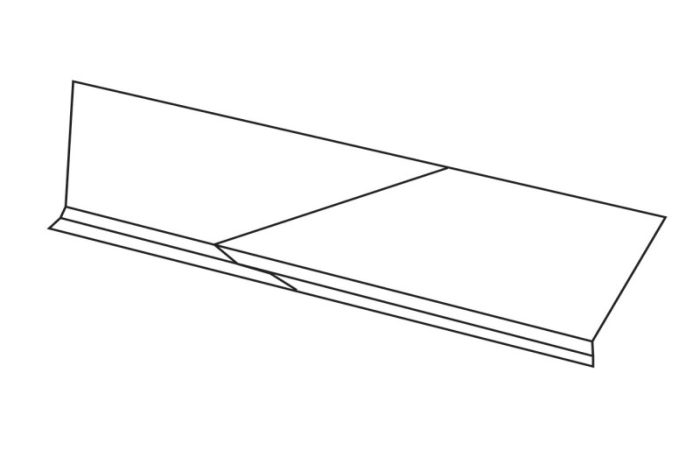

Finger Splice

Double Finger Splice

Skived Splice

Belt Lacing and Installation Tools

Many types of lacing can be installed or replaced on site or at an end user’s facility. This can greatly minimize downtime and cost. Belt Lacing Installation Tools and repair tools are available for a range of lacing systems.

Staple Fastner Tool

Alligator® Ready Set Staple Fastener Tool for use with Alligator staple sizes RS62, RS125 and RS187.

Conveyor belt lacing options, installation tools and repair kits. Mechanical Belt Fasteners use staples, solid plates or hinged plates installed onto belts. Belt ends are joined endless using removable pins or permanent plate connections. Vulcanized Endless Spliced Belts use chemicals or heat vulcanization to join belt ends. This often gives a stronger, permanent splice with no mechanical fasteners. See our conveyor belt overview for conveyor belt basics. Shown below are some of our popular conveyor belt lacing style.

Conveyors

Conveyor Belts, Lacing, Cleats and Repair

Overview and resources on belt conveyor systems, replacement conveyor belts and conveyor belt lacing.